LPG ABOVE TRUCK TRANSPORT (BOBTAIL)

TECHNICAL FEATURES

• Tank Capacity: From 2 m³ up to 35 m³

• Tank Class: Class 2 (Gasses)

• Transported Products: UN 1965 – Hydrocarbon gas mixture

UN 1978 – Propane

UN 1011 – Butane

UN 1075 – Fuel-oil gas, liquefied

• Operating Temperature: between - 50 ‘C and +65 'C

• Design Standard: ADR, EN 12493, EN 12252, TPED, AD2000 Merkblatter, ASME or CODAP

GENERAL FEATURES

• The tank is designed with cylindrical section and is designed with the most durable and lightest combination.

• The tank is designed with a cylindrical section to create the most durable and lightest tank-chassis combination.

• Our tanks use special high strength, fine grained, normalized "P" series pressure vessel steel in accordance with EN 10028-3 standard. The mechanical and metallurgical properties of the steel are tested and verified.

• Elliptical dished head ends are used in the tank headers with stress relieving according to the standards.

• Manufacturing and quality processes are carried out under the supervision of an independent inspection body in accordance with standards and procedures with expert, experienced engineer team.

• Welding is done by certified welders in accordance with standards and materials.

• Tested and controlled by all our welded joints are made by our certified NDT personnel with competent and international validity.

• The inside of the tank is equipped with purge and ring with bolt connection according to the standards.

• Once manufactured, all tanks are subjected to a hydrostatic pressure test. After this test, the connections of the tank accessories are tested with air against leaks.

• Tank exterior surfaces sandblasted to SA 2.5 quality before painting.

• By using the latest technology "Oven Paint" method, the best product is offered by using the corrosion resistant, long lasting, high quality and two component paint products of paint companies which have proved for international quality for painting.

Standard Equipment

• Safety Relief Valves

• Manometer

• Thermometer

• Drainage Nozzle

• DN 450 Manhole

• Fixed Level Indicator ( %2, %85 )

• Rotogauge Indicator

• Hydraulic- driven interval valves

• Rear bumper

• Plastic tool cabinet

• Plastic water tank

• Fire extinguisher cylinder carrying cabin

• Mechanic spare wheel carrier

• Warning and safety marking and labeling

• LPG logo

• Loading and Unloading connections

• Line safety valves

• Line pressure indicator

• Liquid transfer pipe holders (2 units in both sides)

• Earting rod

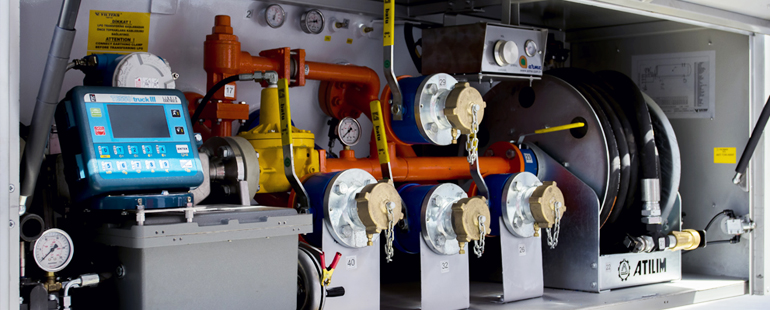

• Qualified and ergonomic valve cabinet made of metal

Optional Equipment

• Magnetic level indicator

• Pneumatically powered interval valves

• Sunshield

• Air ventilation

• Emergency unloading nozzles

• Chrome water tank

• Fire extinguisher cylinders

• Safety system that prevents vehicle movement during operation (Anti tow-away system)

• Stainless valve cabinet

• Inner valve cabinet light fixture

• Remote emergency stop

• Earting reel

• Spare tire

• LPG Transfer Pump

- Hydraulic Pump

- Electrical Driven

• LPG meter and ticket printer

• LPG Hose Reel; Liquid phase, Steam phase or only LPG Pump

- Electrical Automatic winding

- Hydraulic power rewind

- Pneumatic power rewind

• Selectors (used only with LPG Pump)

LPG KAMYONÜSTÜ TRANSPORT TANKI